About PLASTBAU

The PLASTBAU® construction system, is the registered brand name of the internationally patented Swiss technology, established in 1979 by the Research and Development department of Plastedil SA.

The aim was offering the market an innovative and top-quality product for the construction industry. The focus of the PLASTBAU® system is to build with high-quality standards but with lower costs, shorter time and more easily compared to other construction systems. It consists of:

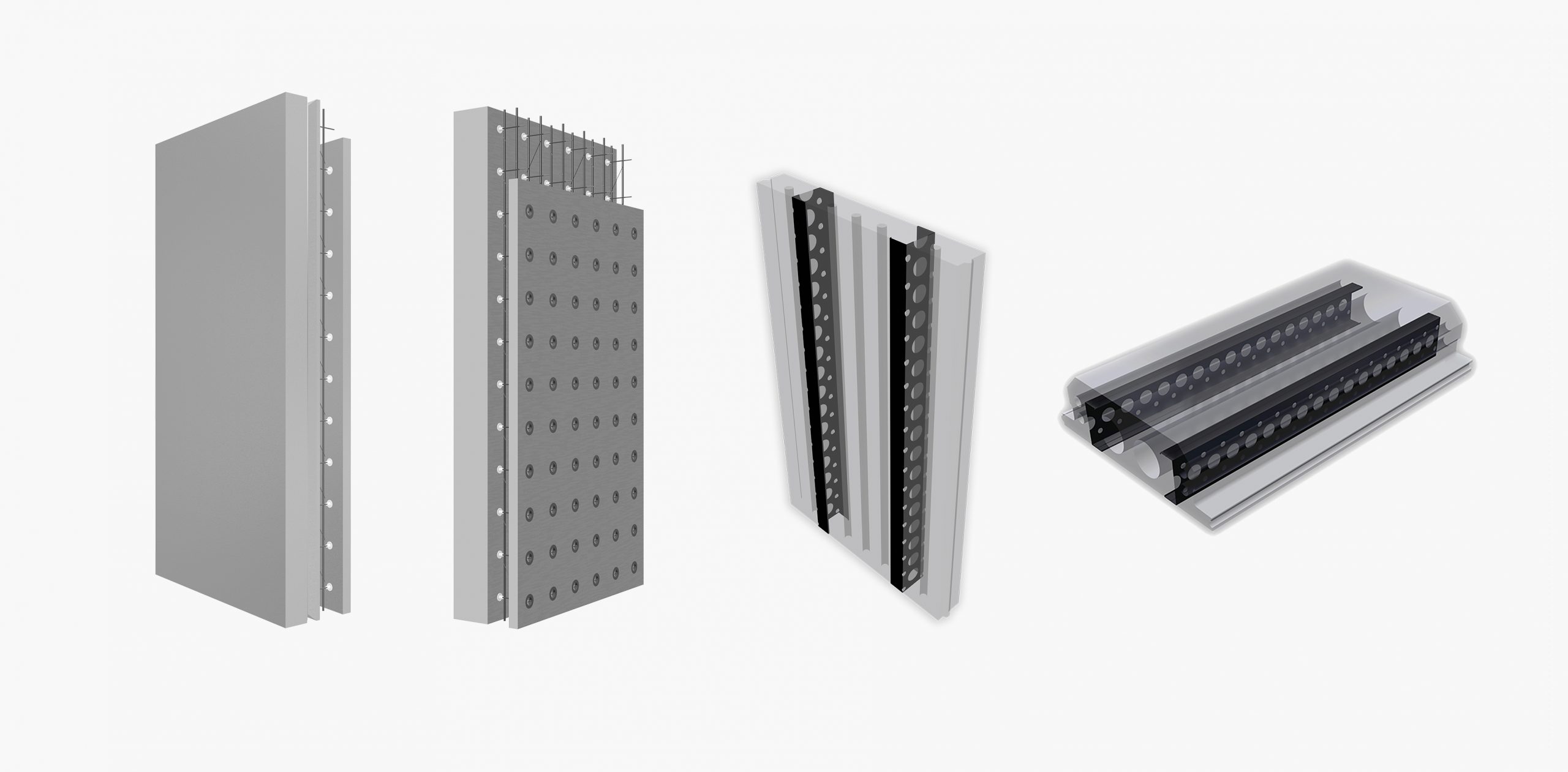

1. A technology for the industrial production of thermally and acoustically insulating, reinforced, stay in-place formworks for the construction industry, using “Flame Retardant” grade Expanded Polystyrene (EPS).

2. By means of the above described insulating formworks, a constructive system which represents the most powerful, complete and versatile method available for constructing reinforced concrete monolithic buildings, with incorporated thermal and acoustic insulation, in any size and form, from cottages to villas, from town-houses to large apartment buildings, from hotels to shopping malls and factories and also for the renovation and consolidation of old buildings because can be easily integrated with other construction systems.

The production of the panels necessary for the construction with the PLASTBAU ® system is realized with specific machinery which can be sized based on the construction needs. Plastedil has the necessary skills and experience to create a Turn-Key Plant to its clients. The EPS panels are made by a continuous moulding process and, when required, the integration with metal elements is realized in line. Through this system, it’s possible to produce external walls, partitions, and floors of great flow and span. The PLASTBAU ®process plants, specifically designed for the production of such (reinforced or non-reinforced) EPS thermo-insulating building elements, normally consist of:

1. Utilities department (for the supplying of the process fluids to the main machinery: steam, water, compressed air).

2. Pre-expansion department (for the pre-expansion of the expandable polystyrene, the recycling of EPS wastes and the feeding of the forming machines)

3. The EPS processing department (for the production of reinforced/non reinforced EPS formworks and panels).

4. The steel working department (to produce the reinforcing metallic cages for the PLASTBAU® 3, PLASTBAU® 5 and the punching of the zinc coated sheets-steel for the PLASTBAU®METAL and PLASTBAU®SIP).

The PLASTBAU® TECHNOLOGY is widespread around the world, its products can be used not only for reinforced concrete structures but also for dry structures.

The flexibility of our system allows to integrate steel frame structures (both heavy and light) and post and beam structures, with our deck panels ready to be filled with concrete. The new trend of insulating and energy saving houses is an easy goal with PLASTBAU®. The great flexibility and easy handling of our products are the best solution to be ready to build any kind of buildings: villas, multifloor buildings, malls, industrial sheds, social houses, box, and much more.

Money Value

Elimination of overuse of steel and concrete. Elimination of beam and pillar wood formworks.

Overall construction costs cut off by 30%.

Construction Speed

The strong reduction of propping, due to the self-supporting capability, and the lightness of the PLASTBAU® elements reduce the construction time by 40%.

Smart Building

The finishing of both internal and external facade is easy and can be done with any commonly available material/finisher on the market. Easy to integrate with plumbing and electrical works.

Eco-friendly

Excellent high thermal-insulation, with great U-values, allows to reduce energetic consumption by 50%, saving money and the eco-sustainability.

Structural Properties

Anti-seismic, anticyclonic and fire resistant up to 180′ are just some of the structural properties of the PLASTBAU® System.

EXCELLENCE SINCE 1963

Plastedil also provides a careful assistance for the start-up, maintenance and technological updating of its machines and plants. Plastedil’s products are extremely user-friendly and assure the best results as far as quality and cost- effectiveness are concerned.

In 1979 Plastedil invented the PLASTBAU® system and built the machine for the moulding of continuous EPS elements reinforced with metallic parts. Since then, our R&D Department, lead by Mr. Cretti, is always working to find new technologies and new solution to be a pioneer of the building market.