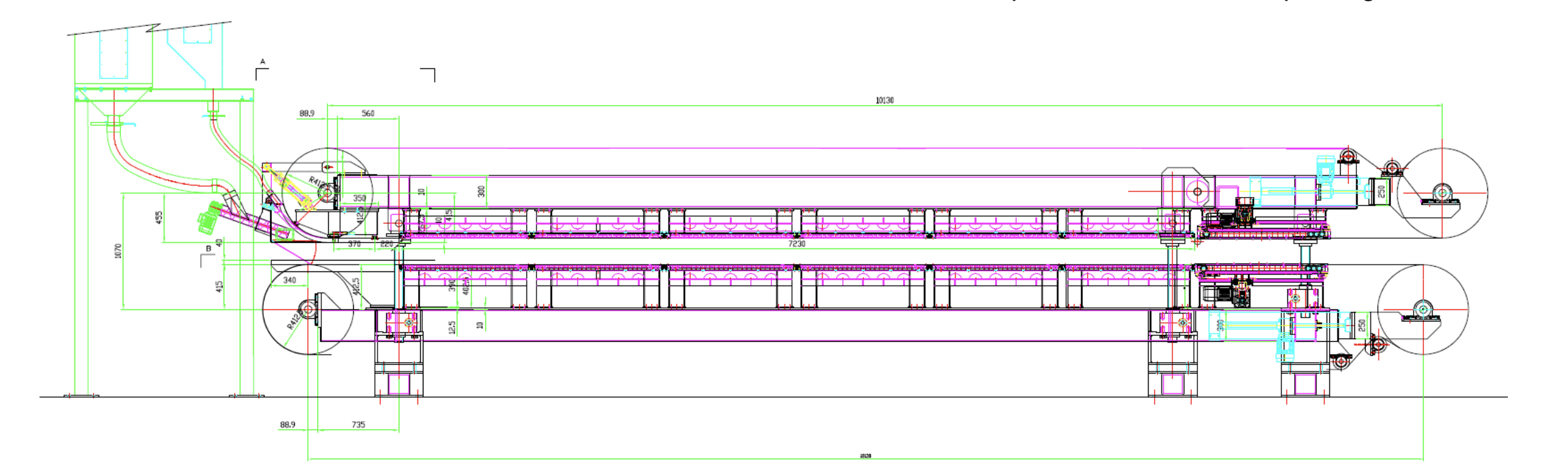

Sintolam SC 600 - Sintolam machinery EPS ETIC insulating panels

The new Sintolam SC-600 is an innovative machinery to produce EPS ETICS insulating panels. The new technology allows us to sintherize panels which are ready to be shipped few hours after the production.

Our EPS ETICS Panels are unique elements, a high-performance insulation sheet. The revolutionary expansion, sintering and lamination process guarantees a perfectly stable EPS Panel. The surface layer in white is inextricably sintered with the Neopor layer (grey EPS), creating a monolithic panel.

- Product homogeneity.

- Textured surface to facilitate plaster adhesion.

- Easy customization with logos and/or colors for technical and marketing purposes.

- Possibility to have a bi-color sheet:

– Grey for better insulating lambda.

– White for greater UV deflection. - Rapid product stabilization:

– Quick response to customer orders.

– Automatically packaged at the end of the line (thanks to production process).

– Low demand for warehouse space.

The special production process allows to syntherize the EPS Panels continuously, without interruptions.

The finished panel is produced in the desired thickness, between 80 and 240 mm, and with the width of 500 or 600 mm, and can be packaged and shipped within 24 hours.

The Sintolam SC-600 can syntherize in one step EPS panels with 2 different densities and 2 different colors.

The production process is in continuous and guarantees an average production of 22-25 m3/h.

The final panels are cut at the desired length of 100 or 120 cm and then stacked, ready to be wrapped and palletized.